April 26 — 29, Hall 06.1, Booth C‑90

We are glad to welcome you.

April 26 — 29, Hall 06.1, Booth C‑90

We are glad to welcome you.

Like fresh

Like fresh

Microwave vacuum drying for sensitive food

Microwave dehydration reimagined. Drying of sensitive products with the wavoniq F12 Center through a safe and easy vacuum process performed under mild conditions. The results will impress you.

ABOUT US

Within our network, we have been creating high-performance applications in microwave technology for many decades. In developing and producing components and subsystems at highest technical level, our main focus has always been on our customers and their needs.

It therefore comes as no surprise that, the wavoniq F12 pushes existing limits right out of the gate

New:

The wavoniq F12

Benefits of the wavoniq F12 Center

Top Result

TOP Result

EXTRAORDINARY DRYING

EXTRAORDINARY DRYING

Ergonomic

Ergonomic

Simple

Simple

Super Fast

Super Fast

highly

Economical

highly

Economical

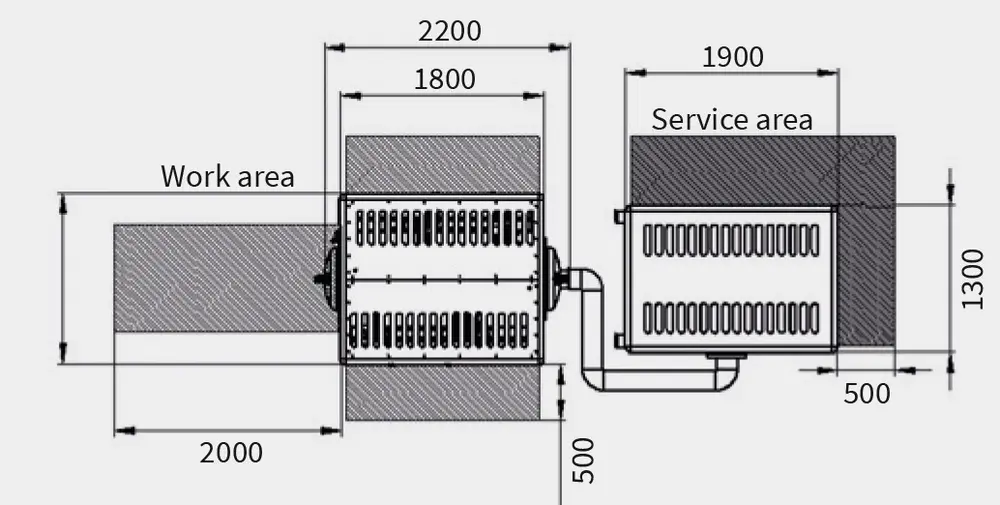

TECHNICAL DATA WAVONIQ F12

| Dimensions (L x W x H) | 1,8 x 1,5 x 2,1 m |

| Dimensions Pump Stand | 1,8 x 1,3 x 1,7 m |

| Microwave power | 12 kW |

| Connected load | 3/N/PE/400V/230/50Hz 63A |

| Weight of material to be dehydrated | 10‒20 kg |

| Drying time | 1‒2 hours* |

INSTALLATION PLAN

Off the shelf?

Not with us!

Customizing the Wavoniq F12

You determine the requirements you have for the drying center. We are at your side and determine together with you whether and which adaptations you need. Our experience enables us to precisely identify your individual situation, translate it into a product and then develop a functioning product. We can achieve all this rapidly, so that you can start production as soon as possible.

Satisfaction Testing

Do you hate to leave anything to chance? So do we! That’s why we’re working at full speed to provide rapid delivery of your wavonig F12 before you invest. This will assure further optimization and perfect mastery of your process. How does that sound? Contact us!